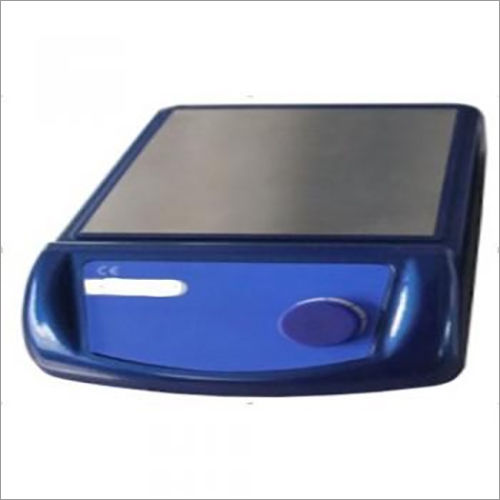

Tablet Friability Tester

Product Details:

X

Product Description

A tablet friability tester is a laboratory equipment used to measure the tendency of tablets to crumble or break when subjected to mechanical stress or abrasion during handling, transportation, or packaging. The test involves placing a sample of tablets in the drum of the friability tester and rotating the drum at a specified speed for a set number of revolutions. The tablets are then removed from the drum and weighed to determine the amount of weight loss due to breakage or chipping.

The tablet friability test is an important quality control test for pharmaceutical companies to ensure that their tablets have sufficient mechanical strength and can withstand normal handling and transportation without losing their integrity. The test is usually conducted according to official pharmacopoeial methods, such as those published by the United States Pharmacopeia (USP) or the European Pharmacopoeia (EP).

The tablet friability tester is typically a compact, benchtop instrument that consists of a rotating drum, a motor, and a control panel for setting the test parameters. The drum is usually made of transparent plastic or glass to allow visual inspection of the tablets during the test. Some tablet friability testers may also have additional features, such as a timer, a counter, or a dust extraction system to minimize the risk of cross-contamination between samples.

Overall, the tablet friability tester is an important tool in the pharmaceutical industry for ensuring the quality and safety of tablets, and is used extensively during the tablet manufacturing process.

Enter Buying Requirement Details