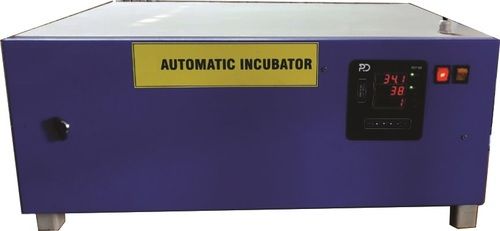

5000 Egg Capacity Fully Automatic Egg Incubator

Product Details:

- Type Incubator

- Material Steel

- Color Yellow

- Technology Automatic

- Weight 260 Kilograms (kg)

- Click to View more

5000 Egg Capacity Fully Automatic Egg Incubator Price And Quantity

- 1 Piece

- 150000 INR/Piece

5000 Egg Capacity Fully Automatic Egg Incubator Product Specifications

- Automatic

- Yellow

- Incubator

- 260 Kilograms (kg)

- Steel

5000 Egg Capacity Fully Automatic Egg Incubator Trade Information

- Mumbai

- Cash Against Delivery (CAD) Telegraphic Transfer (T/T) Letter of Credit (L/C) Western Union Letter of Credit at Sight (Sight L/C) Delivery Point (DP) Days after Acceptance (DA) Cash in Advance (CID)

- 1 Piece Per Day

- 10 Days

- Contact us for information regarding our sample policy

- MDF Sheet

- Australia North America South America Eastern Europe Western Europe Middle East Asia Central America Africa

- CD, FDA, ISI, ISO, BIS

Product Description

SPECIFICATIONS:THE BODY Sturdy and durable body with proper insulation to with stand the impact of atmospheric condition.

THE CONTROL: By pretested contact thermo controls/electronic digital display controls of temperature and humidity through very sensitive sensor.

VENTILATION:Through well balanced multi bladed motorized power impeller fans to such a precise that development in perfect stage.

HUMIDITY: Through sealed type air heaters for normal heating and temperature boosting in cold weather and high altitudes.

COOLING SYSTEM: Achieved through strategically positioned copper pipe cooling coils.(optional)

EXHAUST VENTILATION: Automatic exhaust provided for cooling system.

AUTOMATIC TURNING CONTROL: Designed for every hourly turning of eggs automatically and also provided with electrically controlled rotation recorder Opera table by precise reduction gear box driven by 1/2 H.P.Motor.

SETTING TRAYS: Of high quality specially designed setting trays of plastic to avoid damage to eggs and produce extra hatchability.

ALARM BELL: Caution bell in case of non-confirming atmospheric condition inside the incubator.

HATCHING TRAYS : Of plastic molded, durable and stackable. Designed for proper ventilation, handling and easy to clean.

CONTROL PANEL: Control panels fitted with sensors are provided on front for quick accessibility and machine operation.

ELECTRIC POWER: The system is opera table on 220-250 V, single/Three phase supply.

ELECTRICAL REQUIREMENTS: Fan motor- 1/3 H.P., turning Motor-1/2 H.P., heaters4 no's x 500watts each compartment. Initial load-3 Kw per compartment of setter. Workings load 1-2 Kw per compartment of setter.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+